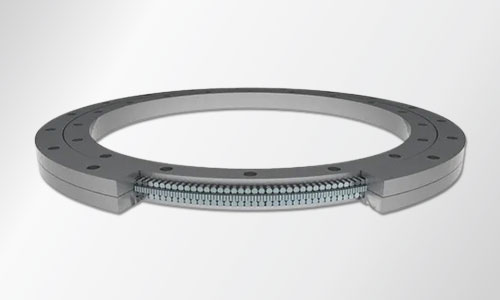

Three Row Roller Slew Ring Bearing

- Home

- Products

Three row roller slew ring bearing

” We are proud to be one of India’s few Three row roller slew ring bearing manufacturers who have developed these products indigenously. We can guarantee that our Three row roller slew ring bearing match global standards and are competitively priced. “

Three row roller slew ring bearing comes in three different parts of ring, upper race, lower race and inner/outer race. The loads coming on each row is different and this is the basic selection criteria for the rollers. Three row roller slew ring bearing is able to carry different loads at the same time, and their load carrying capacity is larger than that of a similar configuration of ball bearing. Since such type of bearings have bigger radial and axial dimensions, these bearings can be used where very heavy loads have to be slewed.

The material that is generally used in these three row roller bearings is En19 or 42CrMO4 which complies with EN10083 and the rolling element, rollers, are made of high chromium steel, which comply with ISO 683-17.

The roller elements are separated by spacers which can be individual or they can be segmented. Some of the heavy bearings incorporate the use of continuous cage, which are usually made from bronze.

The raceways of Three row roller slew ring bearing are hardened by our in-house induction hardening machine to about 56-58 HRC. Before final assembly takes place, the three row roller bearings undergo stringent checks for axial and radial tilting clearance.

Three row roller slew ring bearing is available in the following types:

- Ungeared three row roller bearing.

- Externally geared three row roller bearing.

- Internally geared three row roller bearing.

Slew Ring Bearing details:

- MOC: 42CrMO or C45

- MOC of cage: Nylon 6 / Nylon 66

- Induction Hardening 55 – 58 HRC

- High tilting torque

Application:

- Heavy Duty Cranes

- Wind Mills

- Crawler Cranes

- Radars

Precision turntables and index tables, Test stands and testing equipment, Robotics, Medical diagnostic equipment, Radar and radio telescope antenna.

Crawler crane, marine crane, bucket-wheel excavator, wind turbine, wheeled crane, ladle turret, heavy duty mobile cranes, harbor crane, offshore crane, tunnel boring machine.